THE PERMANENT OVER BAND MAGNETIC SEPARATORS (OBMS)

Suspension Type Permanent Over Band Magnetic Separator are developed to remove tramp metal from the product carried by vibratory feeders, belt, or inclined planes. These are mainly used to safeguard machine such as shedders, Crushers, others and to remove ferrous particles and purify the end products (Industries such as coal Mines, Foundries, Cement Works, food, Sponge Iron Glass, Char Coal, Chemical and Domestic waste recycling Plants)

These Permanent Over band Magnetic Separator are used for an automatic removal of ferrous contamination. For other purposes, fixed permanent Suspension Type Magnets are more suitable.

APPLICATIONS

Several types of separators are developed to operate at pre determined working space over the conveyor i.e. 100,150,200,250 and 300 mm. while choosing the over band, the speed of the belt, the nature of the product, its density, its granulometry and size of the particles, which have to be extracted are the main parmameters to be taken into consideration.

CONSTRUCTION

2 "U" Section pieces are fitted on the magnet by fastening ears and are supporting bearings of drums and the drum are equipped with shafts mounted on removable hubs. All the bearings are equipped with stakes for tightening the belt. Reduction gear coupled Electric Motor/Geared Motors by vee belts drives the belt.

MAGNET UNIT

This Magnet is developed from high Intensity Strontium Ferrite Rare Earth Magnets and guaranteed to give full magnetic power in the entire life span of installation. One Non Magnetic Stainless Steel Plate is supplied to cover the poles of the magnet. No need for electrical supply or maintenance.

INSTALLATION

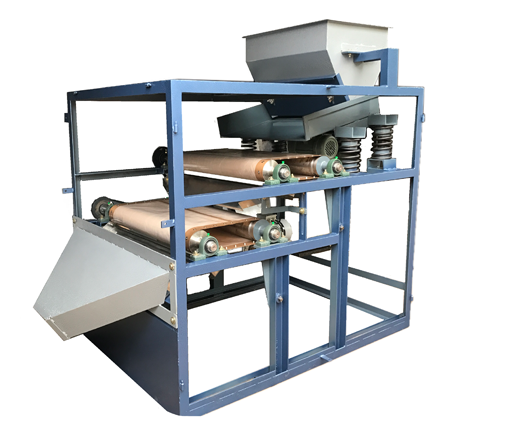

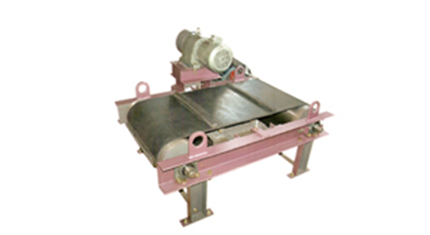

These Magnetic separator can be installed either inline over the terminal head pulley (Image-1) or transversal to the Conveyor (Image-2). For both cases, it is required to foresee Non-magnetic products under the magnetic fileld. Most suitable position is inline (photo-1) over the head pulley. The material being conveyed is in vitual suspension and tramp iron is therefore more readily extracted. Good results are obtained by combining a permanent Magnetic over and with permanent Magnetic pulley at discharge end.