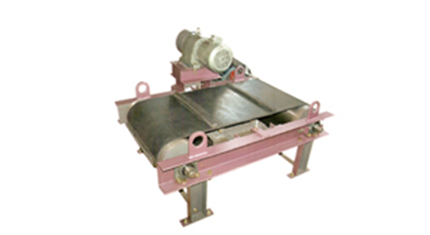

Double Drum Type Permanent Magnetic Separator

Specification : With reduction gear, l HP 3 Phase Electric Motor to drive the drum at a speed of 15 RPM, Vibrating Tray fixed in between Hopper and Drum extra high power permanent magnetic plate at bottom side & Machine complete with close body.

Special modifications can be made as per requirement of the customer.

| Type | Size of the Drum | Capacity | |

|---|---|---|---|

| Dia mm | Length mm | Ton/hour | |

| KI - 767 | 300 | 500 | 1 Ton |

| KI - 768 | 400 | 550 | 1.5 Ton |

| KI - 769 | 400 | 600 | 2 Ton |

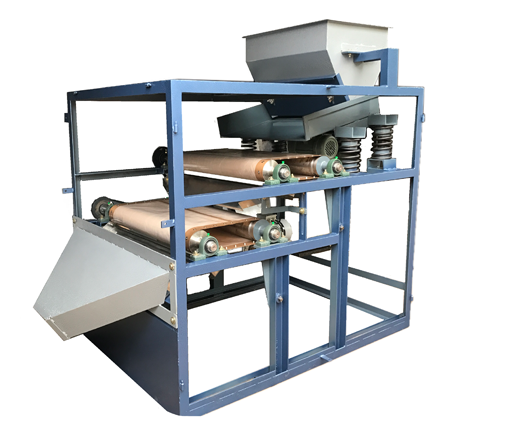

Triple Drum Type Permanent Magnetic Separator

Specification

With reduction gear, 1 HP 3 Phase Electric Motor to drive the drum at a speed of 15 RPM, Vibrating Tray fixed in between Hooper and Drum,extrahigh power permanent Magnetic Plate at bottom side & Machine complete with close body.

| Type | Size of the Drum | Capacity | |

|---|---|---|---|

| Dia mm | Length mm | Ton/hour | |

| KI - 770 | 300 | 500 | 1 Ton |

| KI - 771 | 400 | 550 | 1.5 Ton |

| KI - 772 | 400 | 600 | 2 Ton |

Salient Features

- Drum consists of high coercively modern anisotropic Permanent Magnets.

- Strong & rugged construction.

- Automatic separation of iron impurities.

- Completely closed design to avoid dusting and air pollution.

- Kumar Made Double & Triple Drum Type Permanent Magnetic Separator Manufactured By Well Known Parameters in the Magnetic Field.

- A Unique Device Made From Strong Anisotropic Magnets For Permanent Separating Iron Contents From Powders, Minerals, Chemicals, Food, Flour Plastics, Grains, Sand Cement, Fertilizers, Abrasive, Glass Stag, Ores Rock And Many Other Products.

- Manufactured from extra energetic high retrentivity anisotropic permanent which does not need any electric force.

- Automatic Separation of iron particles in any rang & mesh.

- Build up with strong frame to withstand rough handling.

- It operates on 1 HP Electric Motor.

Permanent Magnetic Drum

Drum manufactured from strong covercivity, strong ceramic magnets. Its radial magnetic design eliminates dead sports and no maintenance is required.

Motor

A 3 Phase or signal phase motor to run the drum.

Vibrating Inlet With Extra Magnetic Plate

To Vibrate the component and flow them to a uniform basis.

Outlet

Fixed with extra magnetic plate to pure the separated material.

Iron collecting Tray

For collecting separated iron from the components.

Hopper

Specially manufactured to flow the material on the drum fitted with continous control on the flow.

Pulleys

Can simply reduce the speed and easily to maintain.